RONDAL

TPF Noob!

- Joined

- Sep 8, 2008

- Messages

- 353

- Reaction score

- 0

- Location

- The Great White North

- Can others edit my Photos

- Photos NOT OK to edit

**edit**

I'm using 2 manfrotto Avenger F1000 suctions, 3 super clamps, and a magic arm.

i've also got 12' of 1.250" aluminum tubing, with wall thickness of 0.058".

When i tested it at the metal shop the flex wasn't that apparent, but now that im testing stuff before going live im getting a TON of pole flex. once i load the end of the pole with the magic arm, super clamp, d90 and wide angle, and amount of bounce in tube is unbearable.

im not getting any sharp images, even when pushing gently on flat ground.

Does anyone have any advice for how to stiffen this up?

I realize i COULD go carbon fibre, but thats like $800 for tubing and im not dropping that yet.

ive been reading all over the place and am looking for suggestions. Whatever the solution, i need it to be portable.

I'm using 2 manfrotto Avenger F1000 suctions, 3 super clamps, and a magic arm.

i've also got 12' of 1.250" aluminum tubing, with wall thickness of 0.058".

When i tested it at the metal shop the flex wasn't that apparent, but now that im testing stuff before going live im getting a TON of pole flex. once i load the end of the pole with the magic arm, super clamp, d90 and wide angle, and amount of bounce in tube is unbearable.

im not getting any sharp images, even when pushing gently on flat ground.

Does anyone have any advice for how to stiffen this up?

I realize i COULD go carbon fibre, but thats like $800 for tubing and im not dropping that yet.

ive been reading all over the place and am looking for suggestions. Whatever the solution, i need it to be portable.

Last edited:

)! You never know what people are up to and thinking these days. My only suggestion is to use a larger/stiffer pole , or as Derrel suggested use a wire and attatch it to the end of the pole pulling down on the pole and attatch it to underneith the car. That way you have all the flex pulled out of the pole. On second thought how far apart are your suction cups? maybe the same size(diameter) pole but a little longer and the sunctions cups spread further apart? Some thoughts for ya, please let us know what you ended up with and maybe some shots of it!

)! You never know what people are up to and thinking these days. My only suggestion is to use a larger/stiffer pole , or as Derrel suggested use a wire and attatch it to the end of the pole pulling down on the pole and attatch it to underneith the car. That way you have all the flex pulled out of the pole. On second thought how far apart are your suction cups? maybe the same size(diameter) pole but a little longer and the sunctions cups spread further apart? Some thoughts for ya, please let us know what you ended up with and maybe some shots of it!

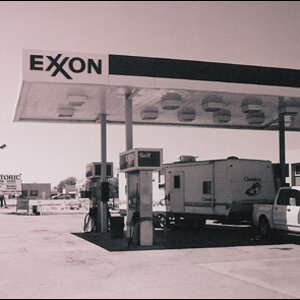

![[No title]](/data/xfmg/thumbnail/37/37525-e6d8ac7dbf90f97648e351449fc9330f.jpg?1619738130)

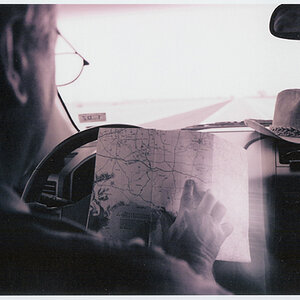

![[No title]](/data/xfmg/thumbnail/40/40412-73276feced223de99c761fc2cc279db5.jpg?1619739461)