TWX

No longer a newbie, moving up!

- Joined

- Apr 30, 2019

- Messages

- 410

- Reaction score

- 103

- Can others edit my Photos

- Photos NOT OK to edit

I ordered a set of five third-party body caps, the intention is to make a pinhole body cap for EF/EFS.

So if I did the math for non-macro right, the hole size is as such:

pinhole diameter = SQRT(2.44 · focal length · wavelength)

Center of the visible light spectrum is around 550nm, or 0.00055mm. Flange distance on a Canon EOS is 44mm, presumably to the back side of the body cap. This yields a pinhole size 0.243mm.

Assuming the body cap is around 4mm thick, the focal length becomes 48mm, this means pinhole is 0.254mm.

The 2.44 number came from a youtube video describing balancing the problems of too-small and too-large pinholes. It applies when the subject is sufficiently distant that as a divisor it approaches irrevelance, versus requiring consideration for macro photography.

So, my game-plan:

Frst I'm going to take some measurements of the body cap and some general measurements on the camera, confirm my numbers, and attempt to find-center on the body cap.

Second, I'm going to look through my drill bits including lathe center-drills, see if I have anything whose point is anywhere close enough. If not then I may have to order something. Grainger has small drills in the ~0.250mm size, as low as $10, and there are whole sets on Amazon that are inexpensive with a variety of sizes.

Third, I'm going to determine if I can make a pinhole accurately in the bare plastic body cap itself, or if I need to make the pinhole in another material and set that into the body cap. I'd rather not use a separate material if I can avoid it.

Fourth, I'd rather hog-out the cone of material from the inside of the body cap (hence the ~48mm calculation) such that the only thing visible on the front of the body cap is the tiniest of pinholes, so probably use some kind of counter-sink bit to drill down to just below the outer face of the body cap, if I am avoiding using a separate material. If I mess this up I can always make the hole bigger and then use separate material.

So if I did the math for non-macro right, the hole size is as such:

pinhole diameter = SQRT(2.44 · focal length · wavelength)

Center of the visible light spectrum is around 550nm, or 0.00055mm. Flange distance on a Canon EOS is 44mm, presumably to the back side of the body cap. This yields a pinhole size 0.243mm.

Assuming the body cap is around 4mm thick, the focal length becomes 48mm, this means pinhole is 0.254mm.

The 2.44 number came from a youtube video describing balancing the problems of too-small and too-large pinholes. It applies when the subject is sufficiently distant that as a divisor it approaches irrevelance, versus requiring consideration for macro photography.

So, my game-plan:

Frst I'm going to take some measurements of the body cap and some general measurements on the camera, confirm my numbers, and attempt to find-center on the body cap.

Second, I'm going to look through my drill bits including lathe center-drills, see if I have anything whose point is anywhere close enough. If not then I may have to order something. Grainger has small drills in the ~0.250mm size, as low as $10, and there are whole sets on Amazon that are inexpensive with a variety of sizes.

Third, I'm going to determine if I can make a pinhole accurately in the bare plastic body cap itself, or if I need to make the pinhole in another material and set that into the body cap. I'd rather not use a separate material if I can avoid it.

Fourth, I'd rather hog-out the cone of material from the inside of the body cap (hence the ~48mm calculation) such that the only thing visible on the front of the body cap is the tiniest of pinholes, so probably use some kind of counter-sink bit to drill down to just below the outer face of the body cap, if I am avoiding using a separate material. If I mess this up I can always make the hole bigger and then use separate material.

Last edited:

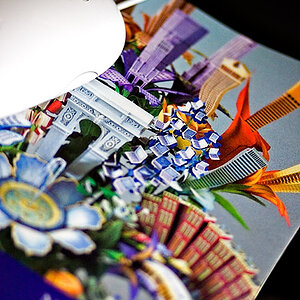

![[No title]](/data/xfmg/thumbnail/32/32805-61ca9a4fb87d37c0ef4f991ac1705e1f.jpg?1619735667)

![[No title]](/data/xfmg/thumbnail/31/31980-e5048a424621c7b3cd0d306d63c09d67.jpg?1619735137)

![[No title]](/data/xfmg/thumbnail/37/37602-1ef8dbb1c2d0e4ff347ee65d328c3603.jpg?1619738147)

![[No title]](/data/xfmg/thumbnail/31/31979-ea92aca54ae865842d998c9cec534991.jpg?1619735137)